NEWS

Snowy Refrigeration

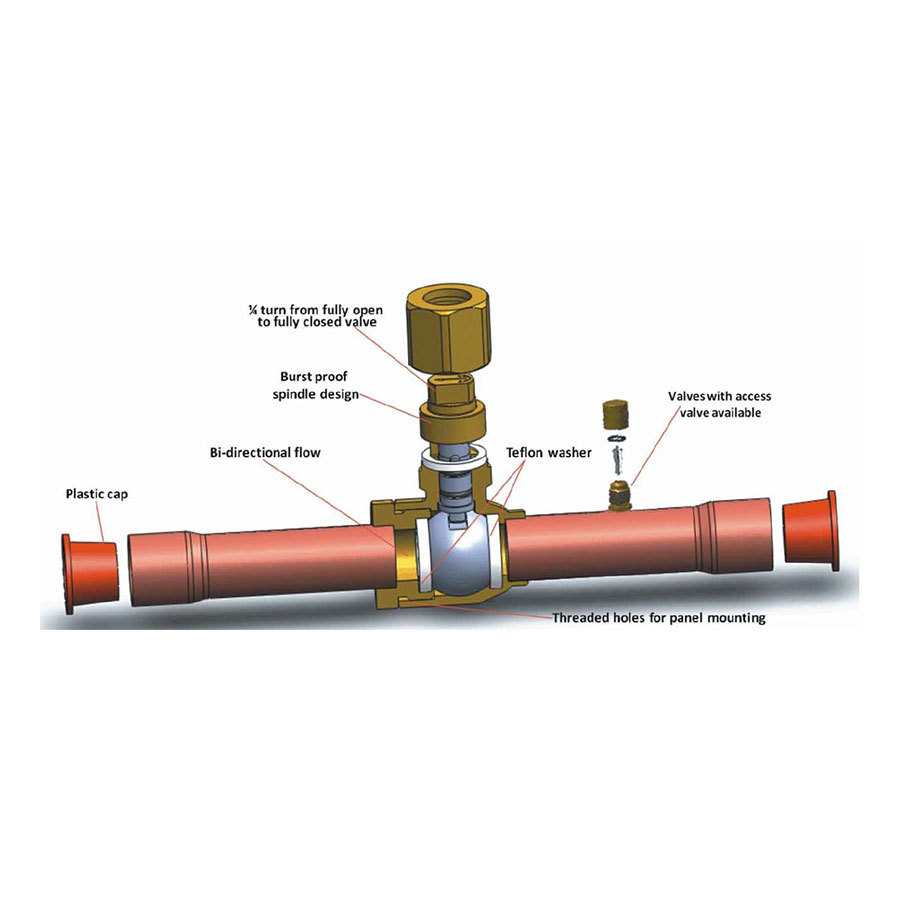

Check points of refrigeration ball valve

Time of issue:

2022-07-11 08:41

Origin:

The daily maintenance cycle and inspection items of the refrigeration ball valve are generally determined according to the characteristics of the production device, the properties of the medium, the corrosion rate and operation conditions, and the characteristics of the valve itself. Inspections generally include the following:

1) Regularly check the lubrication of the oil cup, oil nipple, stem thread and stem nut of the refrigeration ball valve. For the part of the valve with exposed stem, grease or protective cover should be applied to protect it.

2) Regularly check the sealing and tightening of the refrigeration ball valve, and deal with it in time if any leakage or looseness is found. For example, check whether the joints of the refrigeration ball valve are loose, and if they are loose, they should be tightened in time; check whether the packing is outdated and fail, and replace it in time if it is damaged; check the wear or change of the limit position of the refrigeration ball valve switch, and the wear of the sealing surface , and adjust the limit or replace the sealing ring in time.

3) Check the anti-corrosion layer and thermal insulation layer of the refrigeration ball valve, if any damage is found, it should be repaired in time.

4)) Check the parts on the refrigeration ball valve, such as handwheel, handle, etc. If they are damaged or lost, they should be assembled as soon as possible.

5) Regular calibration of refrigeration ball valves should be carried out in strict accordance with the national standards for maintenance and repair of pressure vessels.

refrigeration,ball,valve

Other information